Validation of the Memmert hot air steriliser

Process validation for a Memmert hot-air steriliser is no problem at all. As an example, we have commissioned an accredited testing laboratory to perform a process validation for our SNE 200 and SFP 500 appliances. The test setup was based on the guidelines of the DGKH (German Society for Hospital Hygiene) and the requirements specified in the draft standard ISO/DIS 20857.2 (published as ISO 20857:2010 in August 2010) for the sterilisation of medical products.

Middle level with metal tongs, metal instruments, metal planers, test tubes and Erlenmeyer flasks packed in foil (measuring sensor directly on the chamber load)

The test was performed once without any load, once with mixed load and twice at full load (metallic instruments partially wrapped in plastic or aluminium foil as well as glass containers).

In the SNE 200 steriliser (with a chamber volume of 32 litres), a total of 16 measuring sensors monitored the temperature.

In the SFP 500 steriliser, the larger inner chamber volume of 108 litres made it possible to attach 27 measuring sensors at different positions in the chamber and on the chamber load.

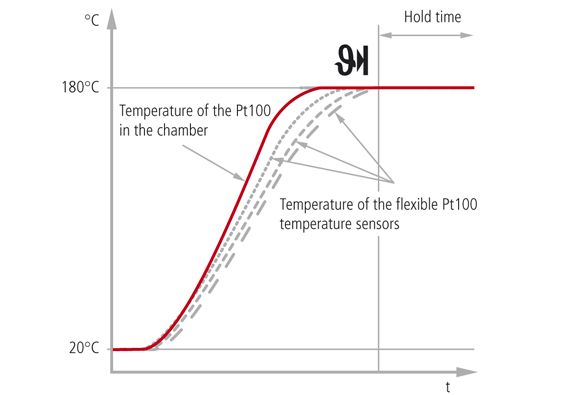

During each measurement, the minimum temperature of 180 °C was reached and maintained for at least 30 minutes at each measuring point.

Lower level with Erlenmeyer flasks (measuring sensor directly on the chamber load)

Unique advantage in competition

With this validation report, the unique competitive edge that the setpoint wait function of the Memmert hot-air steriliser offers, has finally been validated by an independent laboratory.

In addition to the standard Pt100 temperature sensor, up to three external temperature sensors can be integrated in the Memmert hot-air steriliser programme sequence and thus ensure that the sterilisation time does not start before the set temperature has been reached at all measurement points.

Setpoint wait function ensures that sterilisation time is exactly adhered to

If you would like to obtain more detailed information on the topic of validation, the test method and conditions, we will be glad to answer your questions.

Just contact us by Email to info@memmert.be. we will get back to you quickly. Furthermore, we have summed up the relevant facts on the validation of the Memmert hot-air sterilizer in this leaflet.