Menu

MENUMENU

- Products

-

-

-

Here are all temperature control appliances that are classified as medical devices according to the Medical Device Directive for Clinic & Pharmacy.

-

-

-

- Applications

-

-

- Storing sensitive sensors in a climate chamber with a maximum temperature deviation of 0.2 K? Reducing your process times during vacuum drying to an optimum? Ensuring interruption-free long-term testing? Running experiments with defined air exchange rates? Our industrial applications special introduces suitable appliances as well as case studies.It is our hard-lined commitment to quality that has made Memmert a reliable partner in the medical sector and medical research industry ever since the company’s founding in 1947. Of course we are DIN EN ISO 13 485 certified since many years. This medical applications special introduces suitable appliances as well as case studies.It is our passion for details that determines the outstanding quality of our temperature control appliances. And due our unconditional focus on the requirements of the customers Memmert appliances have been regulars in the labs of the pharmaceutical industry and life sciences for decades now. You’ll find corresponding case studies and appliances on this page.We are dedicated to good taste. In order to ensure the unrivalled reliability and precision of Memmert incubators, ovens and climate chambers we develop and manufacture all vital components ourselves. Read more on Memmert’s solutions for the food and beverage industry on our special application page.

-

-

-

- Why Memmert ?

-

-

-

Why Memmert

Memmert is not only a manufacturer of laboratory equipment, but a family business with a long history, a socially responsible employer and a reliable partner.There are many good reasons to opt for a Memmert heating oven, incubator or climate chamber. The 5 most important from intuitive operation to personal after sales service are listed here.Memmert custom design takes care of modifications or develops customized solutions. In the TechLab test runs for special applications can be conducted in Memmert ovens, incubators or climate cabinets.Innovative heating, cooling and operation: take a look behind the scenes in the Memmert technologies topic area.

-

-

-

- Service

- Contact

We know how: When it comes to cell cultivation, active humidification is a must

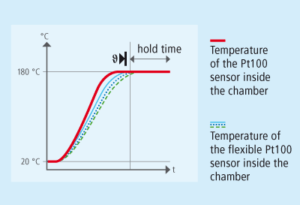

We know how: When it comes to cell cultivation, active humidification is a must We know how: SetpointWAIT function

We know how: SetpointWAIT function We know how: Saving energy

We know how: Saving energy