Energy-saving Peltier-heating and cooling system

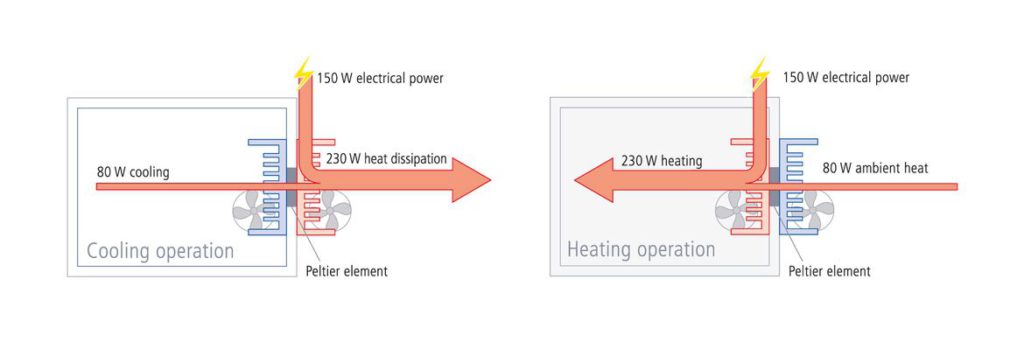

The especially precise, environmentally-friendly, energy-saving heating and cooling system with Peltier technology is used in the cooled incubator IPP, the constant climate chamber HPP and the storage chamber IPS. Heating and cooling in a single system: If a voltage is placed across a Peltier element, one side is cooled and the opposite side simultaneously heats up. Simply by reversing the polarity of the supply voltage, the hot and cold sides of the Peltier element can be swapped.

The Peltier Technology

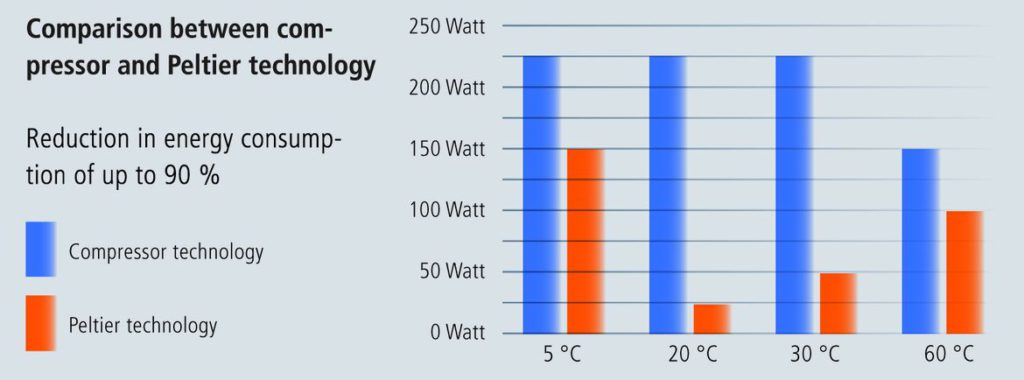

The Peltier technology works in a particularly economical and energy-saving manner at temperatures close to ambient temperature, since energy is only required if heating or cooling is needed, in contrast to compressor technology. Very fine adjustments can be made here to the heating or cooling functions.

Cool with Peltier elements in the IPP refrigerated incubator, HPP climate chamber and IPS storage incubator.

Principle of a heat pump when heating in the cooling incubator IPP, climate chamber HPP and storage incubator IPS.

Peltier elements are probably the best-known industrial application of the Peltier effect. These are connected in series. The contamination with extraneous atoms causes a difference in the conductivity of the two materials. If a voltage is applied to the terminals on the semiconductors, some of the energy is converted into heat. One side of the Peltier element becomes cold, as energy is extracted from it by passing an electrical current through it, while the other side releases the heat extracted from the cold side into the environment. Peltier elements thus function as an electronic heat pump, with which the thermal energy is transported from the cold side to the hot side. Depending on the direction of flow of the current, they can either be used for cooling or for heating.

With Peltier for maximum energy efficiency, precision and versatility

Energy efficiency

With Peltier appliances, in comparison to conventional laboratory appliances with cooling functions based on compressor technology, the ambient thermal energy is converted to heat energy, compensating for up to a third of the heat energy required. The main advantage of Peltier technology is that only the energy that is really needed to keep the temperature constant is used – so for working temperatures close to the ambient temperature, the energy requirements are very low. The degree of effectiveness of appliances with compressors falls drastically from this point onwards, whereas Peltier technology can take full advantage of its superiority in energy efficiency with a savings potential of up to 90 %.

Peltier elements function as a heat pump. During the heating operation the heat energy is extracted from the ambient air and fed to the interior. There is no exchange of outside air and the interior is thus not dehumidified.

The physically induced, unavoidable dripping water during the cooling process does not take place inside the chamber, but outside the working space. In addition, the integrated fans ensure fast energy transport and an optimum temperature distribution.

Peltier devices are an alternative solution considering rising energy costs and increased efforts in environmental protection with regard to economic and ecological aspects.

Precision

Peltier is wonderfully versatile. A Peltier element in a Memmert Peltier-cooled incubator or a Peltier constant climate chamber is switched up to 18,000 times a second, thus enabling extremely sensitive temperature control. The extremely small control fluctuations ensure that tests and processes are repeatable and documentable under precisely defined conditions.

In Addition, the Peltier technology in Memmert appliances heats up and cools down seamlessly in one system and works almost without vibrations and is extremely quiet. Particularly for applications like growing protein crystals, breeding insects, zebra fish and mice, the fact that no loud and unsmooth compressor is required is an invaluable advantage. Of course employees also profit from the pleasant peace and quiet in the laboratory independent of the application, so that, without distraction, they can concentrate on what is essential: their work.

Versatility

Incubation, storage as well as climate control with Peltier-cooled incubators and constant climate chambers. The universally applicable energy savers are used in microbiology, cell culture, food analysis or the electronics industry just the same as for stability testing of food and pharmaceutical products as well as building materials testing.

The Peltier systems are well-engineered that there typically no failure occurs. The devices have a high durability and are almost maintenance-free.