Direct heating of thermoshelf in the vacuum oven

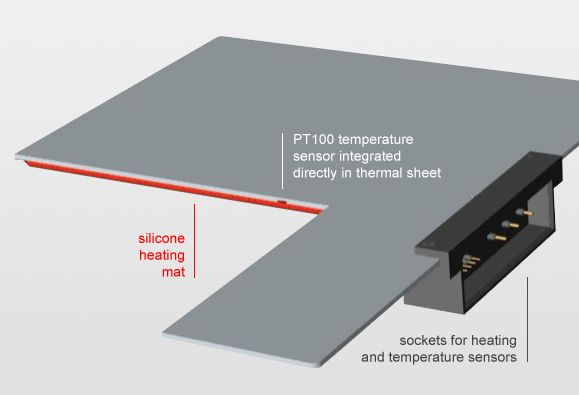

Because the thermal conductivity medium of air is not present in a vacuum, direct contact between heating and the chamber load is absolutely essential. In the Memmert vacuum drying oven VO, the direct heating is vulcanised onto the undersurface of the thermoshelf and protected by an aluminium cover sheet. The advantages for the user: excellent heat transfer, very fast heating-up time and precise controllability.

Optimum temperature distribution and high drying power due to the direct heating with thermoshelves in the vacuum

Each thermoshelf has its own Pt100 temperature sensor, which is also placed inside the centre of the thermoshelf, in close proximity to the chamber load. The special plug developed by Memmert allows the thermoshelf to be removed if necessary, and to be plugged in on different levels, depending on requirements. From the perspective of energy-saving, this is a significant advantage.

To achieve an optimum temperature distribution in the vacuum on all separately heated levels, the thermoshelves are manufactured from anodised and surface-enhanced aluminium as standard. For applications with highly-corrosive materials, we still recommend that you choose stainless steel shelves, because of their resistance to chemicals.