Unbeatably efficient: Memmert Advanced Peltier Technology wins the technology comparison

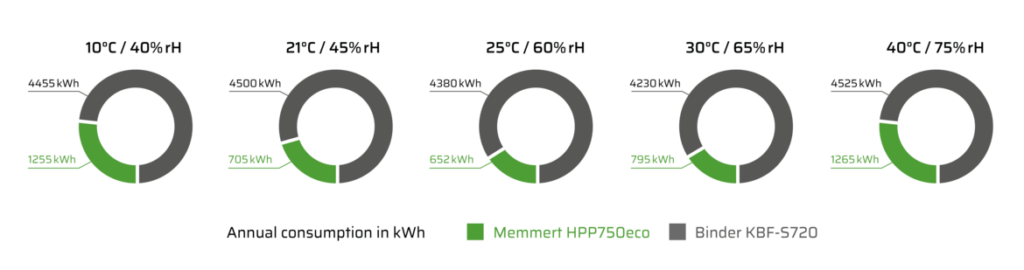

The constant climate chamber HPPeco and the Peltier cooled incubator IPPeco save 85% energy compared to other manufacturers’ standard devices. Testo Industrial Services AG comes to this conclusion after an independent test. This makes our devices more economical than a laptop!

The Memmert HPP750eco, the climate chamber KBF-S720 from Binder, and the Peltier cooled incubator IPP410eco with the Thermo Scientific Heratherm cooled incubator IMP400 were compared. Both test results clearly show that the devices with Memmert Advanced Peltier Technology only consume a fraction of the energy with the same performance. This makes the devices not only more sustainable but also more cost-effective.

All devices were tested under identical conditions in common tests according to ICH Guideline Q1A (R2).

Which technology is best suited for your laboratory application?

No general statement can be made when deciding between compressor or Peltier technology. The focus is always on the specific application and the devices are usually designed for defined processes. Both technologies have specific advantages for the user.

A Peltier device can be made more compact because no additional installation space is required for a refrigeration machine. Due to the small number of mechanical components, such as pumps, filters and piping, the likelihood of failure is lower and maintenance is easier. Maintenance on cooling compressors may only be carried out by specialists with special certification. Peltier elements, on the other hand, can be adjusted in just a few simple steps.

Additionally, Peltier devices work almost vibration-free and quietly due to speed-controlled fan operation. Not using a refrigerant positively impacts ongoing operating costs and climate friendliness. By reversing the current flow, Peltier elements are also used for heating in many devices. This eliminates the need for a separate heat source in the cooled incubator or climatic cabinet. Furthermore, temperature cycles can be run with the same heating-cooling unit.

In laboratory technology, both compressor-cooled devices and Peltier devices offer a very high level of control accuracy. However, Peltier elements react immediately and without a cooling medium, since everything is operated electrically. They can therefore be regulated extremely precisely.

Would you like to see the full test report? Fill in the form below and we will send you the report by e-mail.