Air jacket temperature control handles the chamber load with great care

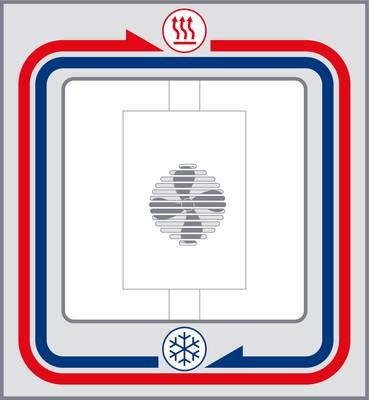

The air jacket temperature control system used in the cooled incubator ICP and the climate chamber ICH ensures an optimum temperature distribution and creates ideal conditions for the chamber load through the especially gentle all-round temperature control of the inner chamber.

Homogenous temperature distribution through air jacket temperature control in the cooled incubator ICP

An air circulation fan placed in the air jacket ensures uniform temperature distribution in the inner chamber, both in heating and in cooling operation. The consistent separation of the air jacket from the chamber prevents the chamber from de-humidifying through the evaporator of the cooling unit. An additional air circulation fan placed in the interior, which if required can be adjusted through the integrated digital speed control to wind-sensitive chamber loads, guarantees a particularly smooth temperature distribution.

All-round constant temperatures in the air jacket, as well as the intelligent automatic defrosting system, prevents ice from forming on the cooling unit underneath the inner chamber.